26 April 1899 – Present

Since 1899, the United States Coast Guard Yard has built, repaired and renovated ships in Baltimore, Maryland, for the U.S. Coast Guard. The history of the Coast Guard Yard heralds scores of success stories and recognizes the shipyard’s vital contributions as a centerpiece of Coast Guard naval engineering for over a century.

1899-1909

In April 1899, the Revenue Cutter Service (RCS) signed a lease with a prominent Baltimore physician and attorney for 36 acres of farmland surrounding Arundel Cove. The doctor and lawyer had previously purchased the 36 acres as part of a 97 acre farm owned and operated by Mr. William Hall, a freed Civil War slave who, at the time, was not only the sole independent farmer of his race in this local vicinity, but was reputed to be the largest African-American farmer in the State of Maryland! Mr. Hall’s property ownership was one of the rarest of all economic achievements in the post-Civil War era for this area. The Yard takes pride in tracing its roots to the inspiring accomplishment of a self-made African-American property owner who overcame tremendous odds and now holds a prominent place in the history of our shipyard.

In June 1899, LT John C. Moore, USRCS, arrived aboard the side-wheeler COLFAX to begin establishment of his experimental shipyard. The following year saw the arrival of the CHASE, a training ship for the RCS. The crew set up permanent quarters at the Arundel Cove “Depot,” marking the beginning of the U.S. Coast Guard Academy. Its floating classrooms remained at Arundel Cove until 1910 when the Academy moved to its present day location in New London, Connecticut. In 1905, Congress authorized the purchase of additional land, and the “Revenue Cutter Station At Curtis Bay” was permanently established. Throughout its first decade, the “Depot” repaired many life-saving boats, constructed a variety of small boats, conducted overhauls, and painted RCS cutters.

1909-1919

The Depot’s facilities were consistently improved upon during the decade of the teens. New construction included a boiler pump house, a foundry, boat, sheetmetal, electrical, paint, upholstery and blacksmith shops, new mess halls, barracks, garages, recreation building and storage structures. The engine school was housed in a shed along the west Depot boundary. When World War I broke out in 1917, the Coast Guard became part of the U.S. Navy and several Navy units were sent to the Depot for repairs and conversion.

1919-1929

During the 1920’s, production of boats, canvas work, and numerous other articles for the needs of the Service was stepped up. Extensive overhauls and repairs were performed on the then-modern vessels YAMACRAW, SENECA, SEMINOLE and many 100’, 125’ and 175’ patrol boats and tugs. The 500 personnel of the Depot included civilian employees along with enlisted personnel. The Depot had gained a nationwide reputation for the fine quality of its work. Its small boats were famed throughout the world, wherever life-saving stations were located or cutters patrolled the seas.

1929-1939

By the 1930’s, many of the original buildings and equipment at the Depot had become outdated. Funds were obtained through Congressional appropriations to modernize the plant. A new boat, gas engine and machine shops were constructed and equipped; a 40-ton marine engine railway was installed. With the transfer of the Lighthouse Service of the Department of Commerce to the Coast Guard in 1939, buoy construction became another major Depot function.

1939-1949

With the advent of World War II, the depot underwent extensive expansion to meet war demands. Improvements included a 3000-ton floating dry dock, two shipways and a 320’ by 60’ concrete pier with tower crane. The Depot, now comparable in size and functions to a medium-size Navy shipyard, was officially designated the U.S. Coast Guard Yard. The shipyard’s work involved repair of scores of surface vessels including submarines, buoy manufacturing, production of canvas work for the Coast Guard, and building over 300 small wooden boats annually. The new work era included the construction of the largest cutters ever built at the Yard – the 255’ cutters MENDOTA and PONTCHARTRAIN. The Yard employed 3100 civilian workers during World War II. Beside the assigned military complement, the Coast Guard’s war time Training Station (Boot Camp) added to the numbers of personnel at the Yard.

1949-1959

As the Yard reduced its workforce to fit the Service’s post-war needs, vessel overhaul, gun repair work, buoy construction and miscellaneous manufacturing made up much of the Yard’s workload. The era of the 50’s saw the construction of three hundred 40’ steel life saving patrol boats, the Coast Guard Lightships SAN FRANCISCO and AMBROSE and small craft like the 36’ 8” motor life boats. In February 1953, the first of the 95’ steel patrol boats was launched at the Yard. In total, fifty-eight 95 footers were built for the Coast Guard and the U.S. Navy throughout the decade of the 50’s into the early 1960’s. In March, 1958, the Coast Guard Cutter AZALEA, a 100’ buoy tender, was launched at the Yard.

1959-1969

The Yard continued to prosper during the decade of the 60’s. The first of fifty-three cutters built at the Yard under the 82’ patrol boat program was launched in February 1960. During the Vietnam conflict, 26 of the Yard-built 82 footers served with distinction as “Coast Guard Squadron One.” In April, 1962, the prototype of the 44’ steel self-righting motor lifeboats was launched. During the next 10 years, the Yard built one-hundred ten 44’ MLB’s. In May, 1965, the Yard sent its first 210’ medium endurance cutter down the shipways, the CGC CONFIDENCE. The 210’ Cutters CONFIDENCE, RESOLUTE, DURABLE, DECISIVE and ALERT were constructed by the skilled hands of the Yard. During the 1960’s and into the early 1970’s, the Yard constructed five 157’ buoy tenders – the RED WOOD, RED BEECH, RED BIRCH, RED CEDAR and RED OAK. Construction began on the RED CEDAR in July, 1969. On the small boat construction side of production during the 60’s, the Yard built two-hundred six 25’8” fiberglass motor surfboats.

1969-1979

The 1970’s engaged the Yard in a flurry of activity. The trades continued the manufacturing of the Coast Guard’s lighted buoys, a program that had begun at the Yard during the Second World War. In 1975, the Yard became the sole source for overhaul of the Coast Guard’s 5”38 caliber gun mount. In 1971, the Yard completed construction of a prototype 41’ utility boat that had an aluminum hull and fiberglass superstructure. The Yard built boat was adopted, and from 1973 through the early l980’s, the Yard constructed two-hundred twenty-seven 41’ search & rescue utility boats. The Yard also has proven record for the design of experimental maritime projects. The construction of the prototype Stable Semi-Submerged Platform, or SSP, was the highlight of the 1970’s. In 1974, the Yard laid the keel for a 160’ single unit construction tender, the CGC PAMLICO. Throughout the remaining decade, three more 160’ construction tenders were built at the Yard: the CGC HUDSON, CGC KENNEBEC and CGC SAGINAW. From the late 70’s into the early 1980’s, the YARD renovated sixteen 95’ patrol boats. Built at the Yard in the 1950’s, these cutters were in need of modernization or repair.

1979-1989

Entering the 1980’s, the Yard constructed a prototype oil skimmer used to clean up oil spills. The Zero Relative Velocity Skimmer, ZRV, represented the best available technology in the Coast Guard’s field of fast current pollution control research. The first of the new 270’ medium endurance cutters, the CGC BEAR, arrived at the Yard in 1983 to begin post construction electronics work, under the program title, 270’ retrofit. The Yard accomplished a retrofit on 12 additional 270’ cutters throughout the 80’s. Beginning in 1984, the Yard began the Service Life Extension Program (SLEP) for nine 180’ buoy tenders in the Coast Guard fleet, giving each an anticipated 20 additional years of service. In 1984, the Yard re-commissioned the first 210’ medium endurance cutter under the Coast Guard’s Major Maintenance Availability Program (MMA). The Cutters, ACTIVE, CONFIDENCE and RELIANCE received their upgrades during the 80’s decade. Eleven more vessels would undergo renovation throughout the 1990’s before the program came to a close. The Yard’s overhaul gave each MMA cutter an anticipated additional 15 years of service life. In 1985, the Yard completed a major renovation of a ferryboat for Coast Guard use at Governor’s Island, New York. The KULSHAN, a 30-year old vessel bought by the Coast Guard from the State of Washington’s ferry system, was renamed the GOVERNOR following renovation at the Yard. As the decade of the 80’s came to a close, the Coast Guard tasked the Yard with construction of six river barges for the Coast Guard use on the Mississippi and Missouri Rivers.

1989-1999

After completing an extensive, four-year repair project on the Coast Guard Barque EAGLE in the 1980’s, the majestic cutter returned to the Yard in 1995 and 1998 for repair availabilities. The Yard built 26 small aids-to-navigation workboats, the 49’ BUSLs from 1997 to 2000. The Yard also completed the 210’ Major Maintenance Availability Program in October, 1998, with the re-commissioning of the cutter DECISIVE. In all, 14 of the Coast Guard’s 210’ cutters underwent an 18-month, $21 million renovation project. The land-based ship handling facility replaced the Yard’s nearly 60-year-old dry dock in l997. The shiplift was environmentally friendly and offered lower maintenance cost. Another milestone in a successful quality journey, the Yard became the first organization in the United States government to achieve ISO 9001 certification in 1995. The Yard became the sole source for major repair of MK 75 weapons systems and worked on both Coast Guard and international weapons systems throughout the l990’s. The Yard expanded its market base in the mid 1990’s to include the overhaul of the Paxman engine, the main propulsion engine in the 110’ patrol boat. The Yard excelled in its capability to bring its expertise to the customer rather than the customer coming to the Yard for service. The Yard built a celebrated reputation for taking its skill “on-the-road” to the Coast Guard fleet world-wide.

1999-2009

In 1999, the Yard celebrated its Centennial, and a year later, saw the dawn of a new millennium and a renewed quest for continued quality service to the Coast Guard fleet. The year 2000 saw an increase in Other Government Agency work such as the renovation of floating causeways for the Defense Department. In 2000, the Yard became the first organization in the Coast Guard and the first shipyard in the U.S. to achieve ISO 14001, receive a second Hammer Award for government improvement initiatives, and its third Unit Commendation Award for fleet readiness. In 2001, the Yard completed the first “Over-the-Horizon Boat” prototype project accommodating the 270’ cutters with faster boat launching systems. In 2001, the Coast Guard Barque EAGLE came to the Yard for a repair availability and experienced its first lift on the land-based ship handling facility. In 2002, the Yard commemorated the first lift of a 378’ cutter, the CGC DALLAS, onto the shiplift and began the 110’ Hull Sustainment Project. That same year, Yard tradesmen renovated several Army and Marine Corp bridge erection boats that would later see action in the Operation Iraqi Freedom. In addition, the Yard manufactured shipping cradles that transported 110’ patrol boats to the Middle East. The ex-Navy steel floating dry-dock OAK RIDGE went into operation at the Yard in 2003, increasing the shipyard’s capability to service the fleet. The Yard initiated its Trades Training Program in 2004, introduced the Critical Chain Project Management Initiative, and received welcomed news at the dawn of 2005 that the Coast Guard would bring the Mission Effectiveness Project to the Yard, a renovation project of the 210’/270’ fleets. In 2006, the Yard received direction from the Coast Guard to expand the Mission Effectiveness Project to include upgrade of selected 110’ patrol boats, including an asset from the Coast Guard Pacific Area. The Yard accomplished numerous scheduled and emergency cutter availabilities, including the first repair for a Great Lakes’ cutter in recent history and a short-notice “roadshow” to renew failed flight deck tie-downs on the CGC DALLAS. That year, the Yard embraced the LEAN business concept of cleaning, eliminating, and organizing a work area to improve production. The Yard graduated its first Trades Training Class in 2007. In September 2008, the Yard accomplished a high-profile road show in Alameda, California, making critical repairs on the newly commissioned Cutter BERTHOLF. In 2009, the Yard’s Electro Group completed the 41′ UTB Electrical Panel & Alarm Upgrade Project on one-hundred thirty-one 41′ utility boats, a nationwide project spanning four years. The Yard opened the Coast Guard’s first Landfill Gas Renewable Energy Center on Earth Day in April 2009. The Center utilized methane gas from a nearby City of Baltimore landfill and converted the gas into two forms of energy – electricity and steam – for use at the Yard.

2009 – 2019

The Yard continues modernization of selected 110′, 210′, and 270′ cutters under the Mission Effectiveness Project. The Coast Guard celebrated the final 210′ modernization under the Mission Effectiveness Project (MEP) at the Yard with completion of the Cutter STEADFAST in the fall of 2009. STEADFAST was the last of fourteen 210′ cutters overhauled at the Yard under the MEP lifecycle sustainment. The Yard’s second Trades Training Class graduated in 2009. The Yard team completed a remarkable emergency availability for the Barque EAGLE in the winter of 2010, despite back-to-back Baltimore blizzards that measured over 4 feet of accumulated snow, setting EAGLE to sea in a record of eight days! The Yard graduated its third Trades Training Class in January 2011. In 2011, the Yard delivered five overhauled 22′ ice rescue airboats from the Coast Guard’s Ninth District for use in search and rescue on the frozen waterways of the Great Lakes and Lake St. Claire, Michigan. In July 2012, the Cutter CHANDELEUR became the 17th and final 110′ patrol boat to undergo modernization under the Mission Effectiveness Project. The Yard began repair availabilities of several cutters of the 87′ patrol boat fleet that year and took the shipyard’s expertise on the road to New London, Connecticut for a dock-side availability of the Barque EAGLE. The Yard accomplished critical emergency repairs in the fall of 2012 on two buoy tenders tasked with search & rescue & aids-to-navigation response during Hurricane Sandy, the second costliest Atlantic hurricane in U.S. history. The fourth Yard Trades Training Class graduated in 2013. The Yard welcomed the final 270′ cutter for overhaul under the Mission Effectiveness Project (MEP) in the summer of 2013. In the summer of 2014, the Cutter MOHAWK was the last 270′ MEP cutter to be delivered, concluding the Mission Effectiveness Project with modernization of fourteen 210′ cutters, seventeen 110′ cutters, and thirteen 270′ cutters over the last nine years at the Yard.

The 140′ icebreaking tug MORRO BAY arrived at the Yard in June 2014 for a 12-month Service Life Extension Project and signaled the beginning of the Coast Guard’s In-Service Vessel Sustainment (ISVS) Program at the Yard. The project is designed to perform life-cycle repairs on select classes of cutters to help vessels meet or exceed their designated service life through a recapitalization of targeted hull, mechanical, electrical and electronic systems. Near term ISVS projects cover select 140′ WTGBs, 225′ WLBs, and the Coast Guard Barque EAGLE. In September 2014, EAGLE arrived to begin the first phase of a four-year Service Life Extension Project under ISVS. The historic ship enters the Yard in the fall and departs each spring to return to the Coast Guard Academy and prepare for summer good will ports-of-call around the world. The Yard became the scene of living history in October 2014 as it welcomed the USS CONSTELLATION for a 4-month availability. The 160-year old Navy “sloop of war” is normally berthed in Baltimore’s Inner Harbor. In November 2014, the 87′ patrol boat IBIS arrived at the Yard as the first cutter to kick off the Coast Guard’s “Bow-to-Stern” project, a 60-day planned maintenance for each of the 47 cutters of the Coast Guard Atlantic Area Coastal Patrol Boat fleet. Work is accomplished under a plastic wrapped scaffolding system, accommodating repair schedules regardless of outside weather conditions. The Yard is accomplishing approximately a dozen bow-to-stern repairs every year, each delivered on time and under budget.

The 140′ icebreaking tug PENOBSCOT BAY arrived at the Yard in February 2015 to begin repair as the 2nd 140′ cutter under ISVS. The Yard welcomed the National Oceanic & Atmospheric Administration (NOAA) Ship FERDINAND R. HASSLER in March 2015 for an eight-week repair availability. The 124′ coastal mapping vessel is the first ship to enter the Yard under an on-going Memorandum of Understanding between the Coast Guard and NOAA for renovation and repair of NOAA vessels. The Yard welcomed the 225′ seagoing buoy tender OAK in June 2015 as the first 225′ cutter for repair under ISVS. The anticipated 14-month overhaul provided a mid-life renovation to meet the vessel’s intended service life. Barque EAGLE returned to the Yard in August 2015 for the second phase of its four-year Service Life Extension Project under ISVS. The Yard completed repair of the second MK75 76mm gun for the Polish Navy in December 2015 under a agreement with the Naval Sea Systems Command for international weapons systems overhauls.

The Yard held graduation for the 5th Trades Training Program in January 2016. There have been five graduating classes with 81 graduates over the past 11 years. The Yard welcomed the second NOAA vessel for repair in March 2016. THOMAS JEFFERSON is a 208′ hydrographic survey vessel outfitted with advanced sonar technology designed to update critical NOAA nautical charts. In March 2016, the Yard completed prototype manufacturing and pre-operational testing/evaluation of an anchor “stinger” for the Coast Guard’s new 154′ Fast Response Cutter fleet. In July 2016, the Coast Guard selected Yard Electro Group General Foreman Ron Viands as the U.S. Coast Guard Senior Civilian Employee of the Year. In September 2016, EAGLE arrived for Phase III of its four-year Service Life Extension Project under ISVS designed to extend the service life of the Coast Guard’s historic training ship. The 225′ seagoing buoy tender WILLOW entered the Yard’s shiplift in October 2016 for the dry-docking phase of its overhaul under the ISVS program. In November 2016, the Yard congratulated Sarah Wickenheiser, Naval Architect, Yard Hull Engineering Branch, as the selected 2017 Coast Guard Engineer of the Year.

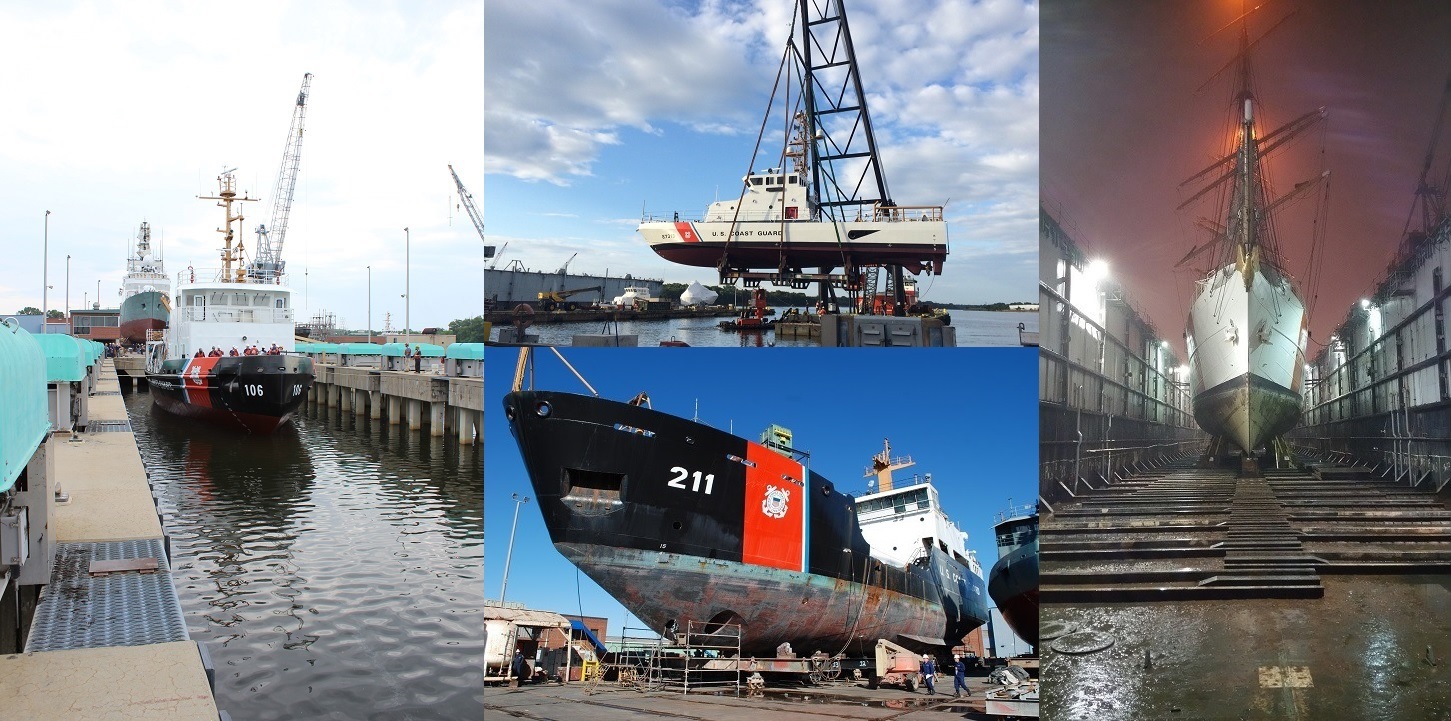

2019 – Present

Construction began in December 2020 to expand the T. Roland Lewis Ship lift. This construction project will provide greater flexibility and capacity for the Yard to meet emergent needs of the current fleet. The project is scheduled for completion summer of 2022.

In 2020, the CG Yard completed a Service Life Extension Project (SLEP) on the ninth 140′ Icebreaking Tug. This was a six year In-Service Vessel Sustainment (ISVS) Program Project, the first of its kind.

CG Yard is currently in production phase of Midlife Maintenance Availabilities (MMA) on CGC SPAR, CGC ALDER, and CGC ASPEN. Three additional hulls are scheduled for the year-long availability before the sixteen-hull program MMA is complete.

Work continues on the 87′ Patrol Boat Recurring Depot Availability Program (RDAP). CG Yard is currently completing work on the 88th such availability and preparing to move into the third and final phase of this program.

Arrival of the 154′ Fast Response Cutter LAWRENCE LAWSON in fall of 2018 kicked off the first of five dry-dock availabilities for the fleet. These availabilities – and the five scheduled to occur before the end of 2023 – are preparing the workforce for a WPC maintenance program modeled from the successful WPB RDAP. In support of this endeavor, CG Yard expects to award a contract for a custom-built RDAP Facility on the west end of the shipyard in summer of 2022 with completion in approximately two years.

Coast Guard Cutter SENECA arrived in the summer of 2021 for the prototype Service Life Extension. Both SSDG and Emergency Generators replaced which included electrical upgrades to SSDG and emergency switchboards. SENECA was utilized as the prototype vessel for ISVS to the 270’ fleet that begins in 2022 with CGC HARRIET LANE.

Coast Guard Cutter SENECA arrived in the summer of 2021 for the prototype Service Life Extension. Both SSDG and Emergency Generators replaced which included electrical upgrades to SSDG and emergency switchboards. SENECA was utilized as the prototype vessel for ISVS to the 270’ fleet that begins in 2022 with CGC HARRIET LANE.

CG Yard Ordnance Shop became the first depot facility to complete full MK110 overhauls, a critical capability in Coast Guard efforts to support the growing NSC and OPC fleet. On top of cultivating new business lines for internal CG support, the CG Yard Ordnance Shop continues to provide technical assistance for a variety of foreign military allies, including the Bahrain, the Philippines, Poland, Saudi Arabia, Taiwan, and Vietnam.

Conclusion

The Yard is proud to have maintained a tradition of maritime excellence that has spanned 119 years and is committed to build on its renowned reputation of quality “Service to the Coast Guard Fleet” well into the 21st century and beyond!